Page 5 - Optc Series

P. 5

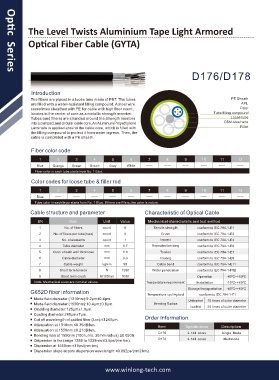

The Level Twists Aluminium Tape Light Armored

Optical Fiber Cable (GYTA)

D176/D178

Optic Series

Introduction

The fibers are placed in a loose tube made of PBT. The tubes PE Sheath

are filled with a water-resistant filling compound. A steel wire APL

sometimes sheathed with PE for cable with high fiber count, Fiber

locates in the center of core as a metallic strength member. Tube filling compound

Tubes (and fillers) are stranded around the strength member Loose tube

into a compact and circular cable core. An Aluminum Polyethylene CSM-steel wire

Laminate is applied around the cable core, which is filled with Filler

the filling compound to protect it from water ingress. Then, the

cable is completed with a PE sheath.

Fiber color code

1 2 3 4 5 6 7 8 9 10 11 12

Blue Orange Green Brown Gray White —— —— —— —— —— ——

Fiber color in each tube starts from No. 1 Blue.

Color codes for loose tube & filler rod

1 2 3 4 5 6 7 8 9 10 11 12

Blue —— —— —— —— —— —— —— —— —— —— ——

Tube color in each layer starts from No. 1 Blue. If there are fillers, the color is nature.

Cable structure and parameter Characteristic of Optical Cable

SN Item Unit Value Mechanical characteristic and test method

1 No. of fibers count 6 Tensile strength conform to IEC 794-1-E1

2 No. of fibers per tube(max) count 6 Crush conform to IEC 794-1-E3

3 No. of elements count 1 Impact conform to IEC 794-1-E4

4 Tube diameter mm 1.7 Repeated bending conform to IEC 794-1-E6

5 Outer sheath wall thickness mm 1.8 Torsion conform to IEC 794-1-E7

6 Cable diameter mm 9.3 Flexing conform to IEC 794-1-E8

7 Cable weight kg/km 90 Cable bend conform to IEC 794-1-E11

8 Short term tension N 1500 Water penetration conform to IEC 794-1-F5B

9 Short term crush N/100mm 1000 Operation -40℃~+60℃

Note: Mechanical sizes are nominal values. Temperature requirement Installation -10℃~+60℃

Storage/transportation -40℃~+60℃

G652D fiber information Temperature cycling test conform to IEC 794-1-F1

Mode field diameter (1310nm):9.2μm±0.4μm. Unloaded

10 times of outer diameter

Mode field diameter (1550nm):10.4μm±0.8μm. Bending Radius loaded

Cladding diameter:125μm±1.0μm. 20 times of outer diameter

Coating diameter:245μm±7μm.

Cut off wavelength of cabled fiber ( cc):≤1260μm. Order Information

Attenuation at 1310nm:≤0.35dB/km. Item Specification Description

Attenuation at 1550nm:≤0.21dB/km.

Bending loss at 1550nm (100 turns, 30mm radius):≤0.05dB. D176 2-144 cores Single Mode

Dispersion in the range 1288 to 1339nm:≤3.5ps/(nm km). D178 2-144 cores Multimode

Dispersion at 1550nm:≤18ps/(nm km).

Dispersion slope at zero dispersion wavelength:≤0.092ps/(nm2 km).

www.winlong-tech.com